Khoom npe: Vuam ceev

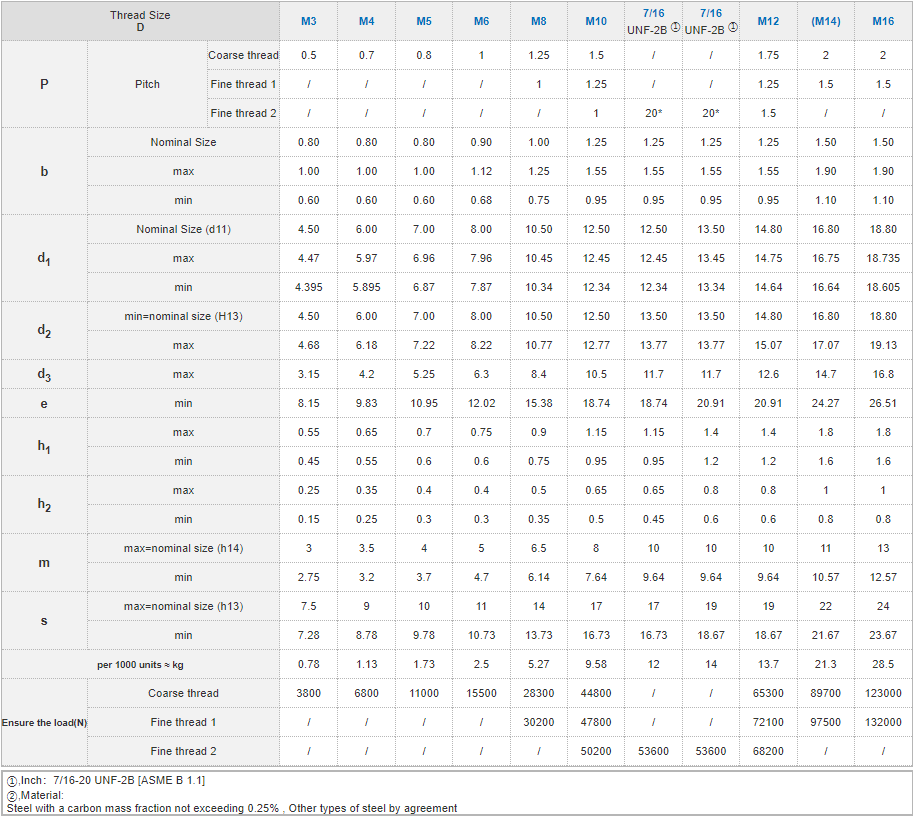

Loj: M8-M24

Qib: 6.

Khoom siv: Hlau / 35k / 45 / 40Cr / 35Crmo

Nto: Plain, Zinc Plated

Qauv: DIN928, DIN929

Piv nrog rau cov txiv ntseej zoo tib yam, cov txiv ntoo vuam zoo dua rau kev vuam.Lawv feem ntau yog ua los ntawm cov ntaub ntawv weldable thiab yog thicker thiab haum rau vuam.Vuam yog sib npaug rau tig ob qhov sib cais rau hauv ib qho tag nrho, melting cov hlau ntawm qhov kub thiab txias thiab sib tov.Tom qab txias ua ke, cov alloys yuav muab ntxiv rau hauv nruab nrab, thiab sab hauv yog cov nyhuv ntawm molecular quab yuam, thiab lub zog feem ntau yog ntau dua li ntawm niam txiv lub cev.Qhov kev sim ntawm vuam tsis yog nyob ntawm qhov fusion loj ntawm cov vuam, thiab cov vuam tsis raug kho raws li qhov loj ntawm fusion kom txog rau thaum qhov tsis xws luag raug tshem tawm.Tau kawg, qhov zoo ntawm vuam yog cuam tshuam nrog kev kho ua ntej vuam, xws li ntxuav, roj stains, thiab lwm yam. Yog li ntawd, kev siv cov txiv ntseej weld yog qhov dav heev.Kev ceev faj rau kev siv cov txiv ntseej welding: 1. Cov roj tiv thaiv yog argon.2. Qhov ntev ntawm tungsten electrode protruding los ntawm cov roj nozzle.3. Qhov ntev ntawm qhov vuam arc yog qhov zoo dua 2 ~ 4 hli thaum vuam zoo tib yam hlau, thiab 1 ~ 3 hli thaum vuam stainless hlau.Yog tias nws ntev dhau lawm, kev tiv thaiv tsis zoo.4. Windproof thiab qhov cua.Nyob rau hauv qhov chaw muaj cua, nco ntsoov ntsuas kev thaiv lub vas, thiab ntsuas qhov cua kom tsim nyog hauv tsev.5. Siv cov khoom siv hluav taws xob nrog cov yam ntxwv ntsug sab nraud, thiab siv cov polarity zoo (cov hlau txuas nrog cov ncej tsis zoo) thaum nws yog DC.6. Nws yog feem ntau haum rau vuam ntawm nyias daim hlau hauv qab 6 hli, thiab muaj cov yam ntxwv zoo nkauj vuam seam zoo thiab me me vuam deformation.7. Txhawm rau tiv thaiv qhov tshwm sim ntawm vuam qhov pores, vuam qhov chaw yuav tsum tau ntxuav yog tias muaj xeb, roj paug, thiab lwm yam. 8. Txhawm rau ua kom cov roj argon zoo tiv thaiv lub vuam pas dej thiab ua kom yooj yim rau kev ua haujlwm vuam, Cov kab nruab nrab ntawm cov tungsten electrode thiab cov khoom ua haujlwm ntawm qhov chaw vuam yuav tsum feem ntau tuav lub kaum sab xis ntawm 80-85 °, thiab lub kaum sab xis ntawm cov xaim xaim thiab qhov chaw ntawm lub workpiece yuav tsum me me li sai tau.Feem ntau hais txog 10 °.

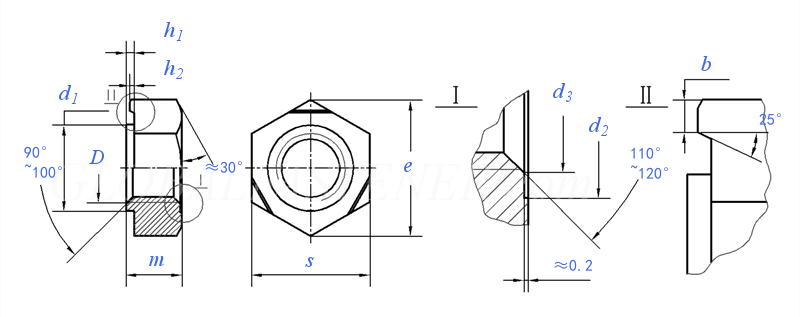

DIN 929 - 2013 Hexagon Weld Ceev